Duct Tape & Gaffer’s Tape

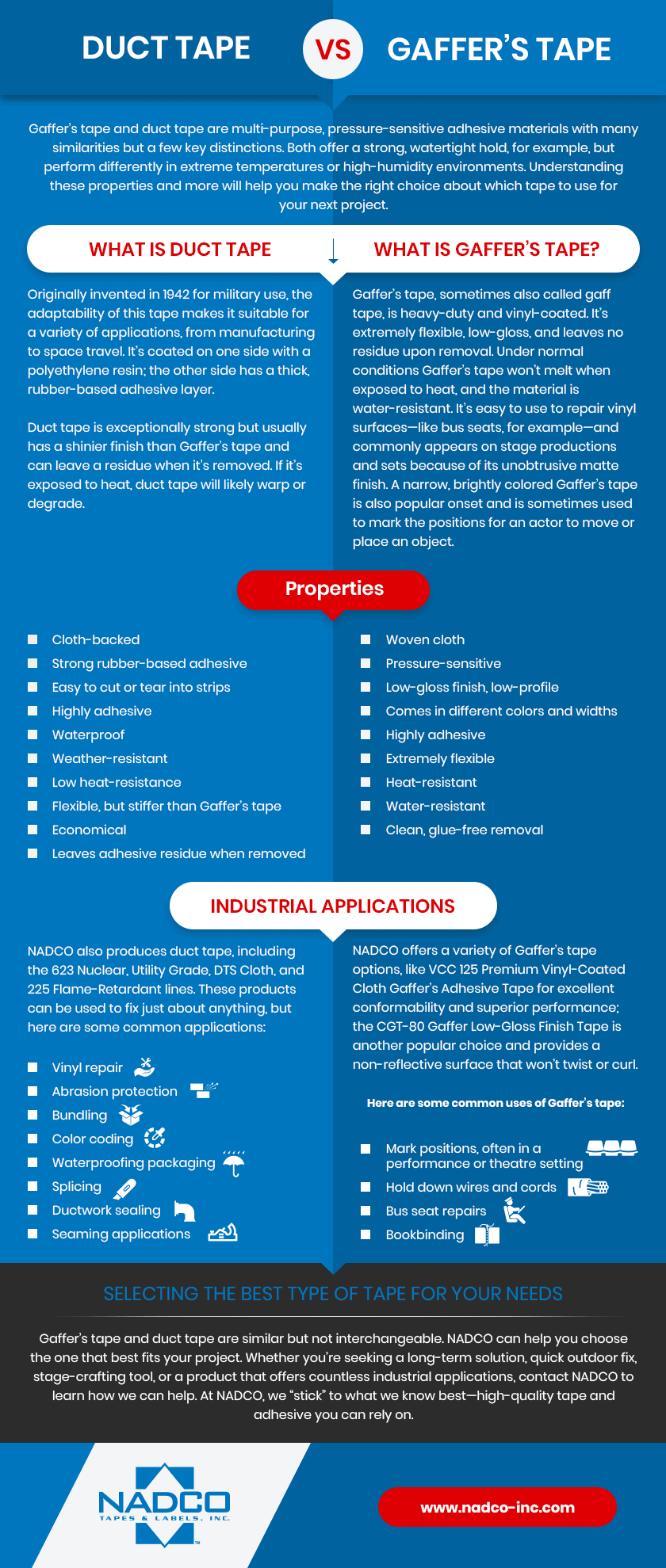

Gaffer’s tape and duct tape are multi-purpose, pressure-sensitive adhesive materials with many similarities but a few key distinctions. Both offer a strong, watertight hold, for example, but perform differently in extreme temperatures or high-humidity environments. Understanding these properties and more will help you make the right choice about which tape to use for your next project.

What Is Gaffer’s Tape?

Gaffer’s tape, sometimes also called gaff tape, is heavy-duty and vinyl-coated. It’s extremely flexible, low-gloss, and leaves no residue upon removal. Under normal conditions Gaffer’s tape won’t melt when exposed to heat, and the material is water-resistant. It’s easy to use to repair vinyl surfaces—like bus seats, for example—and commonly appears on stage productions and sets because of its unobtrusive matte finish. A narrow, brightly colored Gaffer’s tape is also popular onset and is sometimes used to mark the positions for an actor to move or place an object.

Properties of Gaffer’s tape:

- Woven cloth

- Pressure-sensitive

- Low-gloss finish, low-profile

- Comes in different colors and widths

- Highly adhesive

- Extremely flexible

- Heat-resistant

- Water-resistant

- Clean, glue-free removal

Industrial Applications for Gaffer’s Tape

NADCO offers a variety of Gaffer’s tape options, like VCC 125 Premium Vinyl-Coated Cloth Gaffer’s Adhesive Tape for excellent conformability and superior performance; the CGT-80 Gaffer Low-Gloss Finish Tape is another popular choice and provides a non-reflective surface that won’t twist or curl.

Here are some common uses of Gaffer’s tape:

- Mark positions, often in a performance or theatre setting

- Hold down wires and cords

- Bus seat repairs

- Bookbinding

Gaffer’s tape is well-suited for use in hazardous areas, such as inclines and stairwells, and is flexible enough to use on almost any shape and surface.

What Is Duct Tape?

Originally invented in 1942 for military use, the adaptability of this tape makes it suitable for a variety of applications, from manufacturing to space travel. It’s coated on one side with a polyethylene resin; the other side has a thick, rubber-based adhesive layer.

Duct tape is exceptionally strong but usually has a shinier finish than Gaffer’s tape and can leave a residue when it’s removed. If it’s exposed to heat, duct tape will likely warp or degrade.

Duct Tape Properties:

- Cloth-backed

- Strong rubber-based adhesive

- Easy to cut or tear into strips

- Highly adhesive

- Waterproof

- Weather-resistant

- Low heat-resistance

- Flexible, but stiffer than Gaffer’s tape

- Economical

- Leaves adhesive residue when removed

Industrial Applications for Duct Tape

NADCO also produces duct tape, including the 623 Nuclear, Utility Grade, DTS Cloth, and 225 Flame-Retardant lines. These products can be used to fix just about anything, but here are some common applications:

- Vinyl repair

- Abrasion protection

- Bundling

- Color coding

- Waterproofing packaging

- Splicing

- Ductwork sealing

- Seaming applications

Selecting the Best Type of Tape for Your Needs

Gaffer’s tape and duct tape are similar but not interchangeable. NADCO can help you choose the one that best fits your project. Whether you’re seeking a long-term solution, quick outdoor fix, stage-crafting tool, or a product that offers countless industrial applications, contact NADCO to learn how we can help. At NADCO, we “stick” to what we know best—high-quality tape and adhesive you can rely on.