Explore the workings of planetary gear motors, their structure, benefits, challenges, and applications in various industries.

Introduction to Planetary Gear Motors

Planetary gear motors, also known as epicyclic gear motors, are central in many of our modern mechanized systems. Their unique design features and robust performance attributes render them an essential choice for varied applications in industries like automotive, aerospace, robotics, and manufacturing. In this article, we will delve into the concept of planetary gear motors, their structure, and advantages they offer.

Structure of Planetary Gear Motors

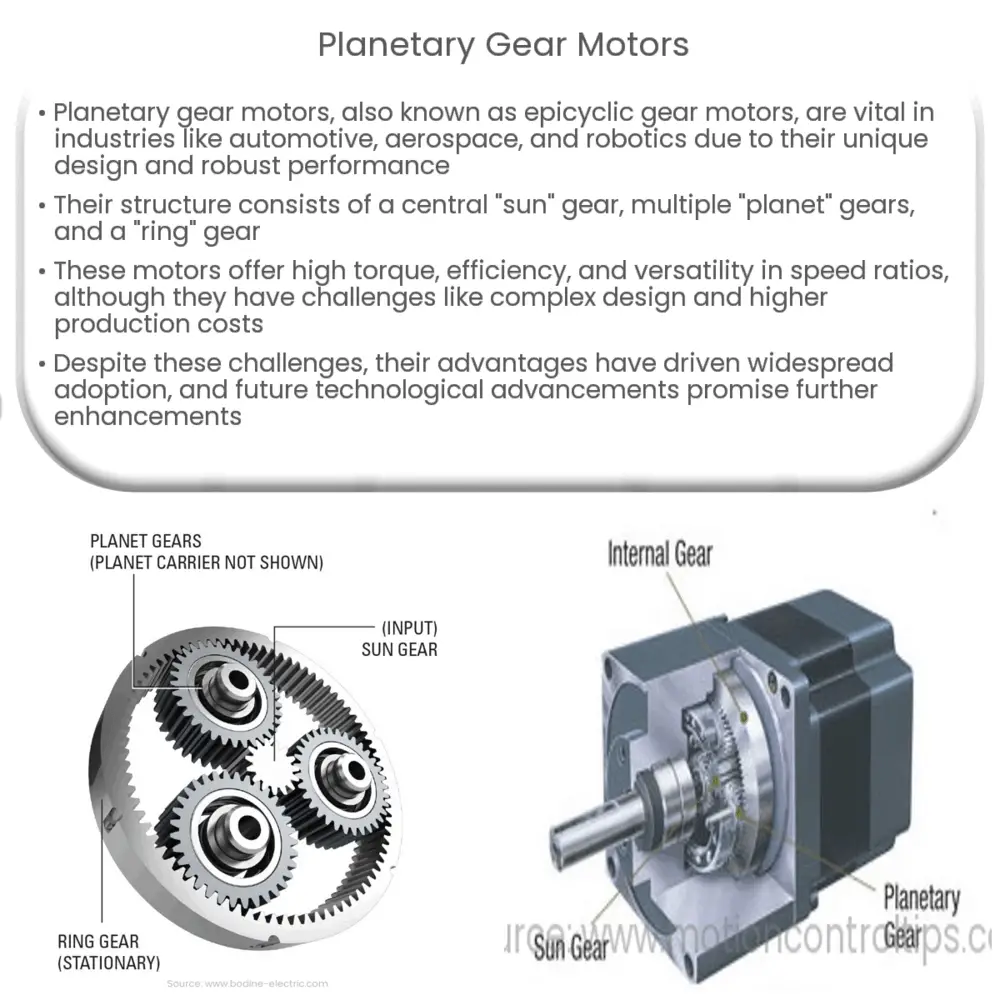

The underlying architecture of a planetary gear motor revolves around the arrangement of gears. A typical planetary gear system comprises three primary components: a central or “sun” gear, multiple “planet” gears, and a “ring” gear. The sun gear resides at the core, with planet gears orbiting around it akin to our planetary system. All these components are enclosed within the ring gear.

- The Sun Gear: The central gear in the assembly. It’s the primary driver gear in most setups, and it’s from this gear that the system derives its name.

- The Planet Gears: These gears orbit around the sun gear. They are held in place by a carrier which also facilitates their rotation.

- The Ring Gear: This is the outer gear with inward-facing teeth, enclosing the entire system.

Operating Principle

The operational efficiency of the planetary gear motor lies in its rotational dynamics. Depending on the configuration, any of the three main components – the sun gear, the planet gears, or the ring gear – can serve as the input, output, or can be held stationary. The remaining components react correspondingly. This makes it possible to achieve varied speed ratios in a compact space.

- Input: The component that receives power from an external source.

- Output: The component that delivers power to perform the work.

- Stationary: The component that is held fixed or immobile during operation.

Advantages of Planetary Gear Motors

Planetary gear motors offer several advantages over traditional gear systems. They provide high torque to size ratio, excellent efficiency, low vibration, and the flexibility to deliver different speed ratios. Moreover, the load is distributed amongst multiple planet gears, leading to higher load capacity. However, these benefits come with their own set of challenges, which we’ll discuss in the next part of this article.

Challenges in Planetary Gear Motors

Despite the numerous benefits, planetary gear motors do come with a few challenges. One of the most significant is their inherent complexity, requiring precision in design and assembly. The production process can be expensive due to the requirement of high-quality materials and meticulous machining for efficiency and longevity.

- Complex Design: The design of a planetary gear motor is more complicated than conventional gear systems. This complexity increases the need for precision in manufacturing and assembly.

- Cost: Due to the high precision requirements, the production costs of planetary gear motors can be higher than traditional gear systems.

Applications of Planetary Gear Motors

Despite these challenges, the advantages of planetary gear motors have led to their widespread use in various sectors. Some of the prominent applications are:

- Automotive Industry: In automobiles, they are used in transmissions to provide different speed ratios.

- Aerospace: In the aerospace industry, they are employed in satellite positioning systems.

- Industrial Applications: They are used in conveyor belts, cranes, and other machinery for providing high torque output.

Future of Planetary Gear Motors

With advancements in technology, the use of planetary gear motors is expected to rise further. Developments in materials science may lead to lighter, stronger, and more efficient gear systems. Simultaneously, innovations in manufacturing processes could potentially bring down costs, making these motors more accessible for various applications.

Conclusion

Planetary gear motors, with their unique design and functional benefits, have revolutionized many industries by offering high torque output, efficiency, and flexibility in speed ratios. Despite the challenges associated with their complexity and cost, their advantages continue to drive their adoption in various sectors. The future holds exciting prospects for these motors, with advancements in technology poised to augment their performance and accessibility. As we move towards a more mechanized future, the role of planetary gear motors will undoubtedly become increasingly crucial.